Top Quality Rim - Plastic Injection – Protom Detail:

Plastic Injection

Protom is used to working on both low and high volume production runs, depending on your project requirements. We can provide highly price-competitve solutions for low to medium-volume production requirements for your business. Production volumes of 500 to 100,000 parts can be produced at a reasonable cost per piece. All commercially available plastic materials are available., and we provide various kinds of surface finishing services, including plating, painting, silk screening, pad printing and hot stamp printing.

Design for Manufacture (DFM)

Design for Manufacture is a helpful tool that we can provide to our customers to help minimize tooling costs and to help expedite the manufacturing process.

We will provide you with a detailed report that contains important information about your part design and highlights any potential problem areas.

In addressing design issues early on, the DFM helps to eliminate costly re-tooling or delays in the manufacturing process caused by a problematic part design.

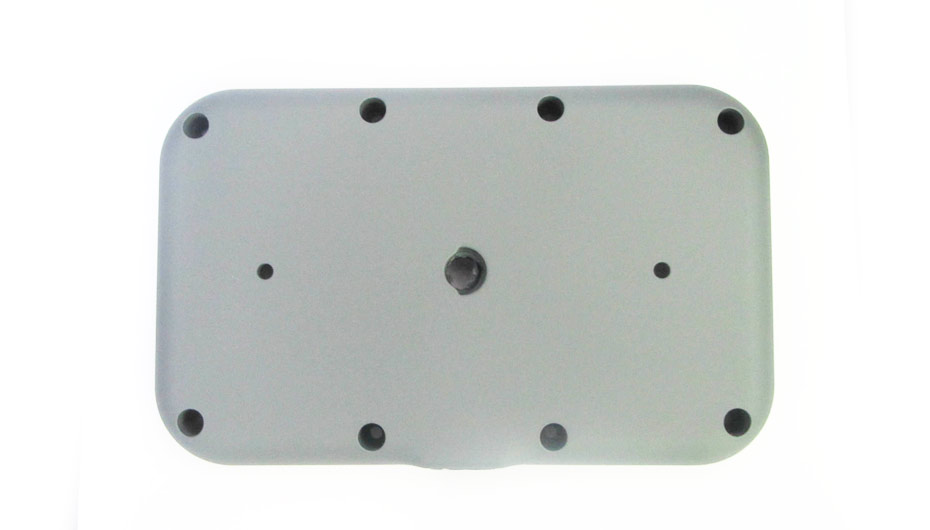

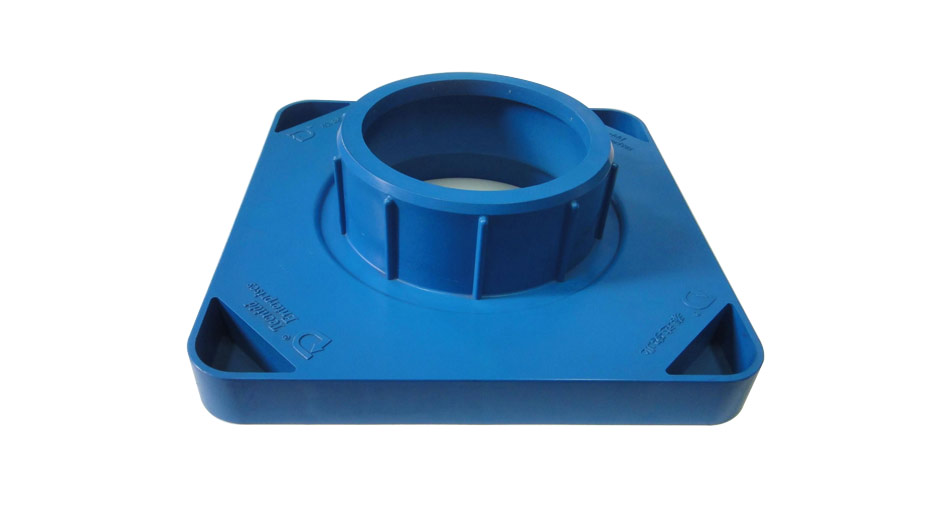

Product detail pictures:

Related Product Guide:

Cooperation

We insist on offering premium quality manufacturing with superior business concept, honest product sales as well as finest and fast assistance. it will bring you not only the good quality product or service and huge profit, but the most significant is to occupy the endless market for Top Quality Rim - Plastic Injection – Protom, The product will supply to all over the world, such as: Slovenia , Florida , Suriname , As a way to use the resource on the expanding info in international trade, we welcome prospects from everywhere on the web and offline. In spite on the high quality items we offer, effective and satisfying consultation service is supplied by our qualified after-sale service group. Item lists and detailed parameters and any other info weil be sent to you timely for the inquiries. So please make contact with us by sending us emails or call us when you've got any questions about our organization. ou could also get our address information from our site and come to our enterprise. We get a field survey of our merchandise. We are confident that we'll share mutual accomplishment and create solid co-operation relations with our companions within this market place. We're seeking forward for your inquiries.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!