Top Quality Rim - Plastic Injection – Protom Detail:

Plastic Injection

Protom is used to working on both low and high volume production runs, depending on your project requirements. We can provide highly price-competitve solutions for low to medium-volume production requirements for your business. Production volumes of 500 to 100,000 parts can be produced at a reasonable cost per piece. All commercially available plastic materials are available., and we provide various kinds of surface finishing services, including plating, painting, silk screening, pad printing and hot stamp printing.

Design for Manufacture (DFM)

Design for Manufacture is a helpful tool that we can provide to our customers to help minimize tooling costs and to help expedite the manufacturing process.

We will provide you with a detailed report that contains important information about your part design and highlights any potential problem areas.

In addressing design issues early on, the DFM helps to eliminate costly re-tooling or delays in the manufacturing process caused by a problematic part design.

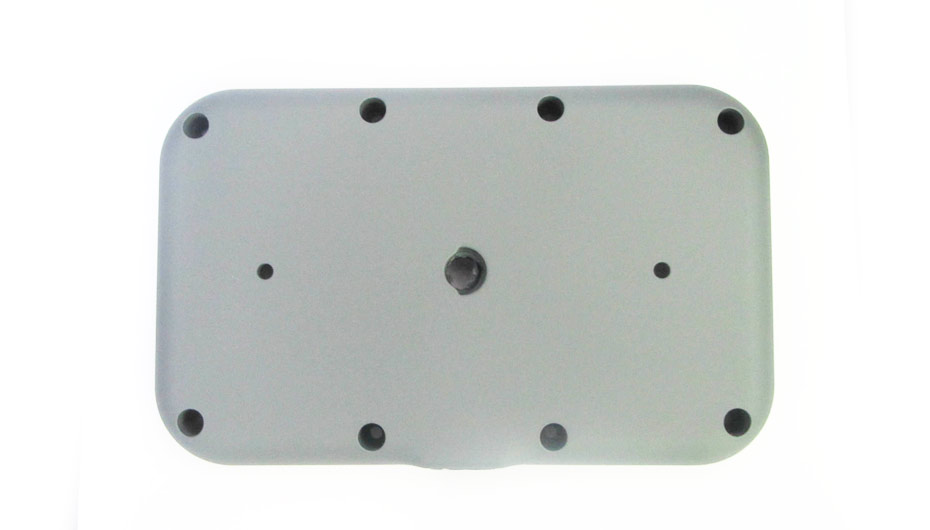

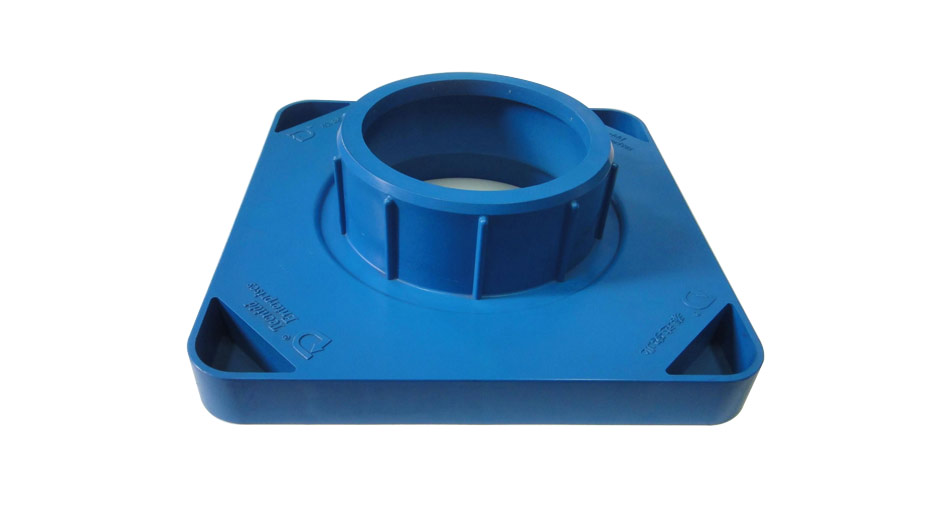

Product detail pictures:

Related Product Guide:

Cooperation

With our superb management, potent technical capability and strict quality command procedure, we go on to provide our shoppers with trustworthy high-quality, reasonable costs and outstanding services. We goal at becoming considered one of your most trustworthy partners and earning your pleasure for Top Quality Rim - Plastic Injection – Protom, The product will supply to all over the world, such as: Moldova , Colombia , Barbados , We welcome you to visit our company & factory and our showroom displays various products that will meet your expectations. Meanwhile, it is convenient to visit our website. Our sales staff will try their best to provide you with the best services. If you need more information, please do not hesitate to contact us via E-mail, fax or telephone.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.