OEM Supply Molding Supplier - Soft Tooling – Protom Detail:

Rapid Tooling

With orders of more than 100 parts, we will consider Quick Turn Tooling, Injection Molding for plastics and Die Casting for metals. Materials could be plastics and metals. We can make rapid tooling for various plastics with different finishing, like sand blasting, texture, painting, plating and so on, depending on our customers’ requirements.

What is rapid tooling?

Rapid Tooling is a way to simplify the mold structure for low cost & short lead-time. It’s commonly used in the field of rapid injection molding, based on the low-volume requirement. Nice Rapid manufactures its own rapid tooling in 7075 aluminum(mold can be textured) and pre-hardened P20 tool steel, to make the cavity, core and ejector plates. They are then fitted into a Master Unit Die(MUD based system) with standard tooling components, in order to produce injection molded parts.

Rapid Tooling vs Conventional Tooling?

Aluminum tooling is very suitable or low-volume production prototype runs, providing a cost effective solution with shorter lead-time than traditional production tooling. For rapid tooling, we can typically be 30-50% cheaper than full production tooling, with a 40-60% reduction in lead-time compared to traditional

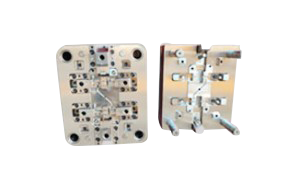

Product detail pictures:

Related Product Guide:

Cooperation

We stick to our enterprise spirit of "Quality, Performance, Innovation and Integrity". We purpose to create a lot more price for our prospects with our rich resources, innovative machinery, experienced workers and great products and services for OEM Supply Molding Supplier - Soft Tooling – Protom, The product will supply to all over the world, such as: Haiti , New Orleans , Canada , Our staffs are rich in experience and trained strictly, with qualified knowledge, with energy and always respect their customers as the No. 1, and promise to do their best to deliver the effective and individual service for customers. The Company pays attention to maintaining and developing the long-term cooperation relationship with the customers. We promise, as your ideal partner, we'll develop a bright future and enjoy the satisfying fruit together with you, with persisting zeal, endless energy and forward spirit.

Speaking of this cooperation with the Chinese manufacturer, I just want to say"well dodne", we are very satisfied.