OEM Supply Metal 3d Print - Soft Tooling – Protom Detail:

Rapid Tooling

With orders of more than 100 parts, we will consider Quick Turn Tooling, Injection Molding for plastics and Die Casting for metals. Materials could be plastics and metals. We can make rapid tooling for various plastics with different finishing, like sand blasting, texture, painting, plating and so on, depending on our customers’ requirements.

What is rapid tooling?

Rapid Tooling is a way to simplify the mold structure for low cost & short lead-time. It’s commonly used in the field of rapid injection molding, based on the low-volume requirement. Nice Rapid manufactures its own rapid tooling in 7075 aluminum(mold can be textured) and pre-hardened P20 tool steel, to make the cavity, core and ejector plates. They are then fitted into a Master Unit Die(MUD based system) with standard tooling components, in order to produce injection molded parts.

Rapid Tooling vs Conventional Tooling?

Aluminum tooling is very suitable or low-volume production prototype runs, providing a cost effective solution with shorter lead-time than traditional production tooling. For rapid tooling, we can typically be 30-50% cheaper than full production tooling, with a 40-60% reduction in lead-time compared to traditional

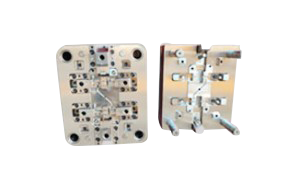

Product detail pictures:

Related Product Guide:

Cooperation

We've got a really efficient group to deal with inquiries from prospects. Our purpose is "100% customer fulfillment by our product excellent, price & our group service" and enjoy a superb track record amid clientele. With many factories, we can easily deliver a wide selection of OEM Supply Metal 3d Print - Soft Tooling – Protom, The product will supply to all over the world, such as: Germany , Serbia , Stuttgart , Facing fierce global market competition, we have launched the brand building strategy and updated the spirit of "human-oriented and faithful service", with an aim to gain global recognition and sustainable development.

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.