OEM Supply Metal 3d Print - Soft Tooling – Protom Detail:

Rapid Tooling

With orders of more than 100 parts, we will consider Quick Turn Tooling, Injection Molding for plastics and Die Casting for metals. Materials could be plastics and metals. We can make rapid tooling for various plastics with different finishing, like sand blasting, texture, painting, plating and so on, depending on our customers’ requirements.

What is rapid tooling?

Rapid Tooling is a way to simplify the mold structure for low cost & short lead-time. It’s commonly used in the field of rapid injection molding, based on the low-volume requirement. Nice Rapid manufactures its own rapid tooling in 7075 aluminum(mold can be textured) and pre-hardened P20 tool steel, to make the cavity, core and ejector plates. They are then fitted into a Master Unit Die(MUD based system) with standard tooling components, in order to produce injection molded parts.

Rapid Tooling vs Conventional Tooling?

Aluminum tooling is very suitable or low-volume production prototype runs, providing a cost effective solution with shorter lead-time than traditional production tooling. For rapid tooling, we can typically be 30-50% cheaper than full production tooling, with a 40-60% reduction in lead-time compared to traditional

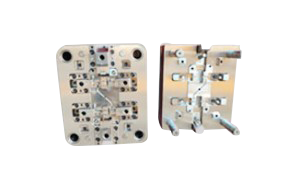

Product detail pictures:

Related Product Guide:

Cooperation

Our merchandise are broadly identified and trusted by end users and can satisfy continually developing economic and social requires for OEM Supply Metal 3d Print - Soft Tooling – Protom, The product will supply to all over the world, such as: Czech Republic , Nigeria , Palestine , Thus far, our item associated with printer dtg a4 may be shown in most foreign nations as well as urban centers, which are sought after simply by targeted traffic. We all highly imagine that now we have now the full capacity to present you with contented merchandise. Desire to collect requests of your stuff and produce the long-term co-operation partnership. We very seriously promise:Csame top quality, better price; exact same selling price, higher quality.

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.