Manufactur standard Anodizing - Plastic Injection – Protom Detail:

Plastic Injection

Protom is used to working on both low and high volume production runs, depending on your project requirements. We can provide highly price-competitve solutions for low to medium-volume production requirements for your business. Production volumes of 500 to 100,000 parts can be produced at a reasonable cost per piece. All commercially available plastic materials are available., and we provide various kinds of surface finishing services, including plating, painting, silk screening, pad printing and hot stamp printing.

Design for Manufacture (DFM)

Design for Manufacture is a helpful tool that we can provide to our customers to help minimize tooling costs and to help expedite the manufacturing process.

We will provide you with a detailed report that contains important information about your part design and highlights any potential problem areas.

In addressing design issues early on, the DFM helps to eliminate costly re-tooling or delays in the manufacturing process caused by a problematic part design.

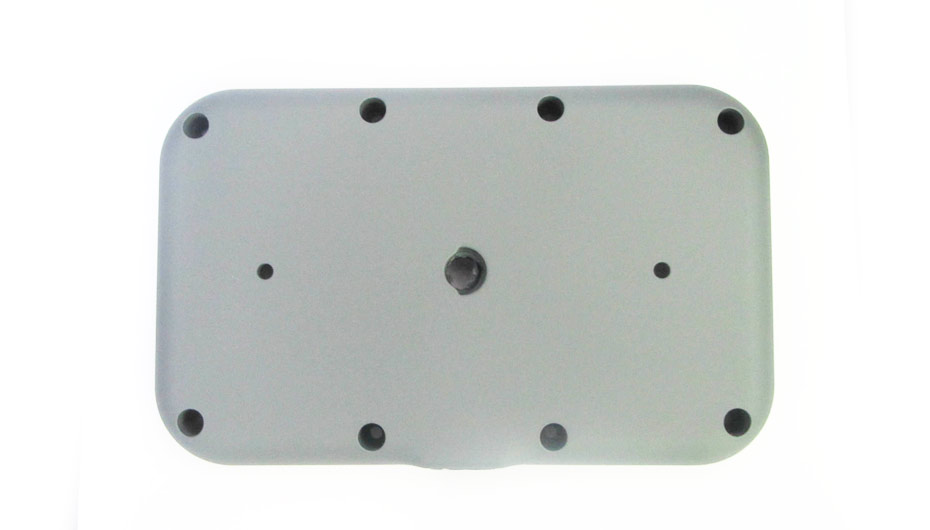

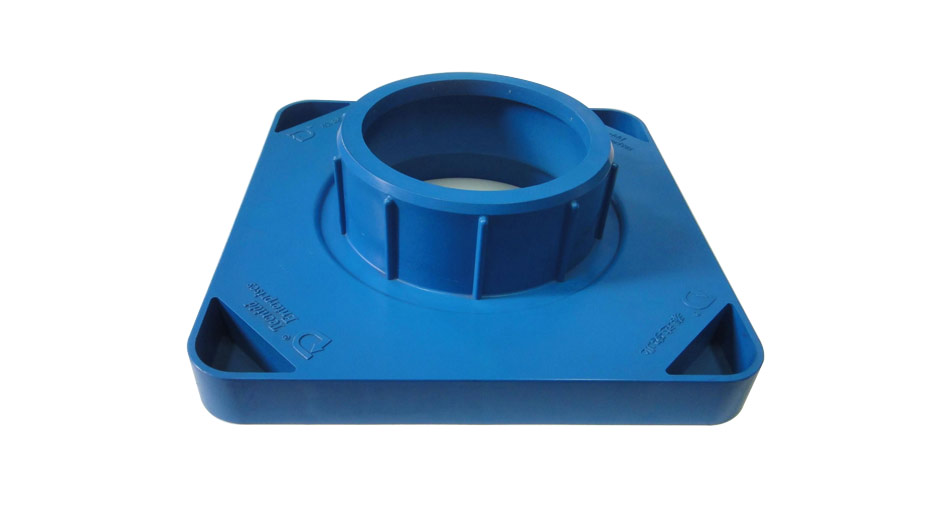

Product detail pictures:

Related Product Guide:

Cooperation

Our concentrate on should be to consolidate and enhance the quality and service of present products, meanwhile consistently produce new products to meet unique customers' demands for Manufactur standard Anodizing - Plastic Injection – Protom, The product will supply to all over the world, such as: United Arab emirates , Guatemala , Tajikistan , Our products are mainly exported to Europe, Africa, America, the Middle East and Southeast Asia and other countries and regions. We have enjoyed a great reputation among our customers for quality products and good services.We would make friends with businessmen from at home and abroad, following the purpose of "Quality First, Reputation First, the Best Services."

Good quality, reasonable prices, rich variety and perfect after-sales service, it's nice!