China Rapid Machining Supplier – Plastic Injection – Protom Detail:

Plastic Injection

Protom is used to working on both low and high volume production runs, depending on your project requirements. We can provide highly price-competitve solutions for low to medium-volume production requirements for your business. Production volumes of 500 to 100,000 parts can be produced at a reasonable cost per piece. All commercially available plastic materials are available., and we provide various kinds of surface finishing services, including plating, painting, silk screening, pad printing and hot stamp printing.

Design for Manufacture (DFM)

Design for Manufacture is a helpful tool that we can provide to our customers to help minimize tooling costs and to help expedite the manufacturing process.

We will provide you with a detailed report that contains important information about your part design and highlights any potential problem areas.

In addressing design issues early on, the DFM helps to eliminate costly re-tooling or delays in the manufacturing process caused by a problematic part design.

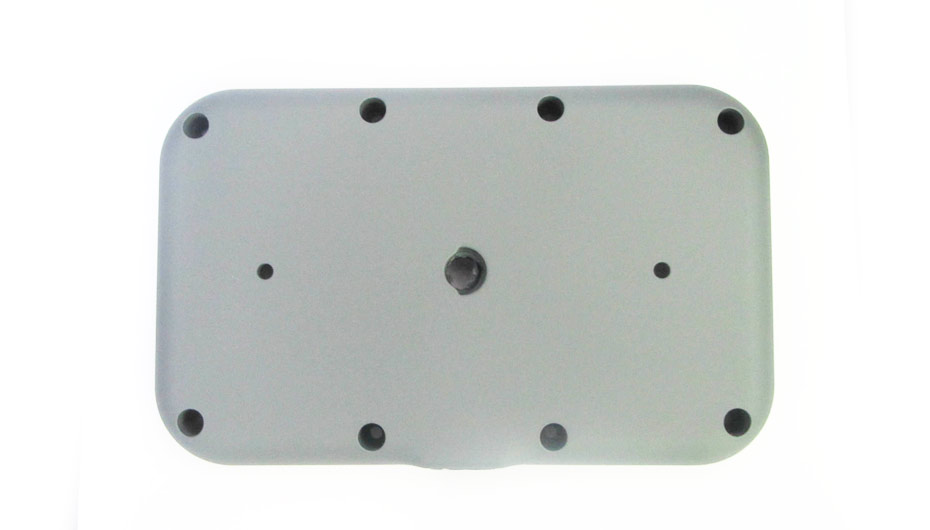

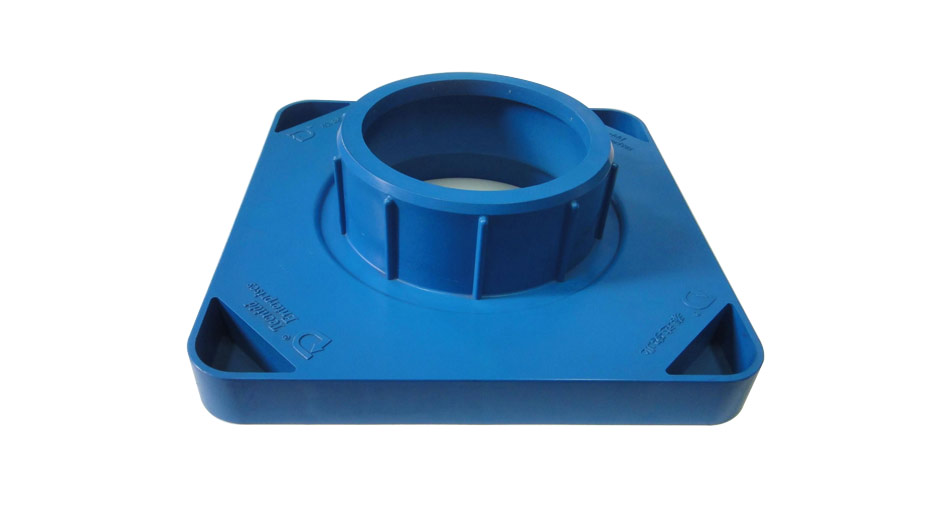

Product detail pictures:

Related Product Guide:

Cooperation

Our mission is to become an innovative supplier of high-tech digital and communication devices by providing value added design, world-class manufacturing, and service capabilities for China Rapid Machining Supplier – Plastic Injection – Protom, The product will supply to all over the world, such as: Florida , Danish , US , We solution have passed through the national skilled certification and been well received in our key industry. Our specialist engineering team will often be ready to serve you for consultation and feedback. We've been able to also provide you with no cost samples to meet your needs. Best efforts are going to be produced to supply you the very best service and solutions. For anyone who is considering our business and solutions, please speak to us by sending us emails or get in touch with us right away. As a way to know our items and enterprise. lot more, you'll be able to come to our factory to find out it. We'll constantly welcome guests from around the globe to our firm. o build enterprise. elations with us. You should really feel absolutely free to make contact with us for small business and we believe we'll share the top trading practical experience with all our merchants.

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,