China Plastic Injection Tooling Supplier – Soft Tooling – Protom Detail:

Rapid Tooling

With orders of more than 100 parts, we will consider Quick Turn Tooling, Injection Molding for plastics and Die Casting for metals. Materials could be plastics and metals. We can make rapid tooling for various plastics with different finishing, like sand blasting, texture, painting, plating and so on, depending on our customers’ requirements.

What is rapid tooling?

Rapid Tooling is a way to simplify the mold structure for low cost & short lead-time. It’s commonly used in the field of rapid injection molding, based on the low-volume requirement. Nice Rapid manufactures its own rapid tooling in 7075 aluminum(mold can be textured) and pre-hardened P20 tool steel, to make the cavity, core and ejector plates. They are then fitted into a Master Unit Die(MUD based system) with standard tooling components, in order to produce injection molded parts.

Rapid Tooling vs Conventional Tooling?

Aluminum tooling is very suitable or low-volume production prototype runs, providing a cost effective solution with shorter lead-time than traditional production tooling. For rapid tooling, we can typically be 30-50% cheaper than full production tooling, with a 40-60% reduction in lead-time compared to traditional

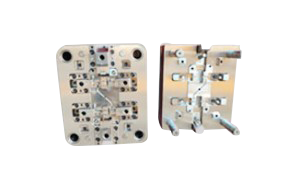

Product detail pictures:

Related Product Guide:

Cooperation

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of China Plastic Injection Tooling Supplier – Soft Tooling – Protom, The product will supply to all over the world, such as: Egypt , Kuwait , Estonia , Based on our automatic production line, steady material purchase channel and quick subcontract systems have been built in mainland China to meet customer's wider and higher requirement in recent years. We have been looking forward to cooperating with more clients worldwide for common development and mutual benefit!Your trust and approval are the best reward for our efforts. Keeping honest, innovative and efficient, we sincerely expect that we can be business partners to create our brilliant future!

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.