8 Year Exporter Mechanical Design - Plastic Injection – Protom Detail:

Plastic Injection

Protom is used to working on both low and high volume production runs, depending on your project requirements. We can provide highly price-competitve solutions for low to medium-volume production requirements for your business. Production volumes of 500 to 100,000 parts can be produced at a reasonable cost per piece. All commercially available plastic materials are available., and we provide various kinds of surface finishing services, including plating, painting, silk screening, pad printing and hot stamp printing.

Design for Manufacture (DFM)

Design for Manufacture is a helpful tool that we can provide to our customers to help minimize tooling costs and to help expedite the manufacturing process.

We will provide you with a detailed report that contains important information about your part design and highlights any potential problem areas.

In addressing design issues early on, the DFM helps to eliminate costly re-tooling or delays in the manufacturing process caused by a problematic part design.

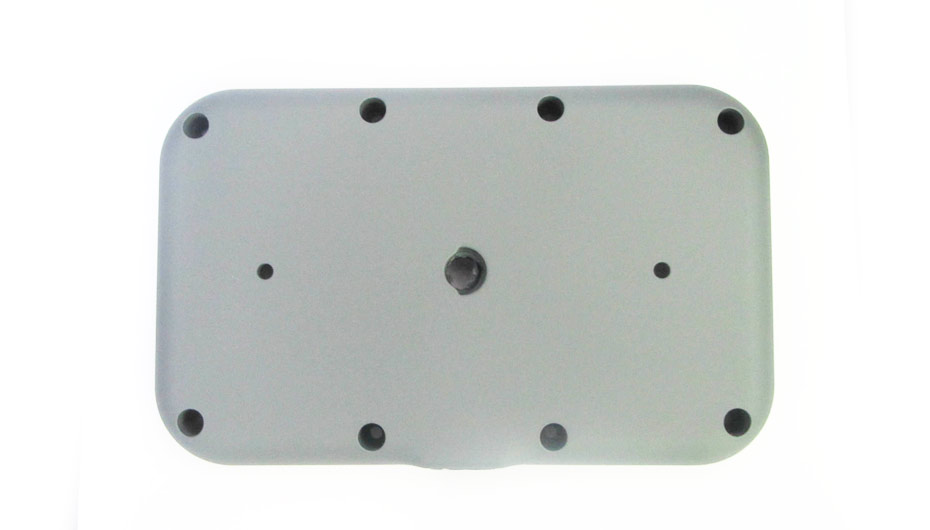

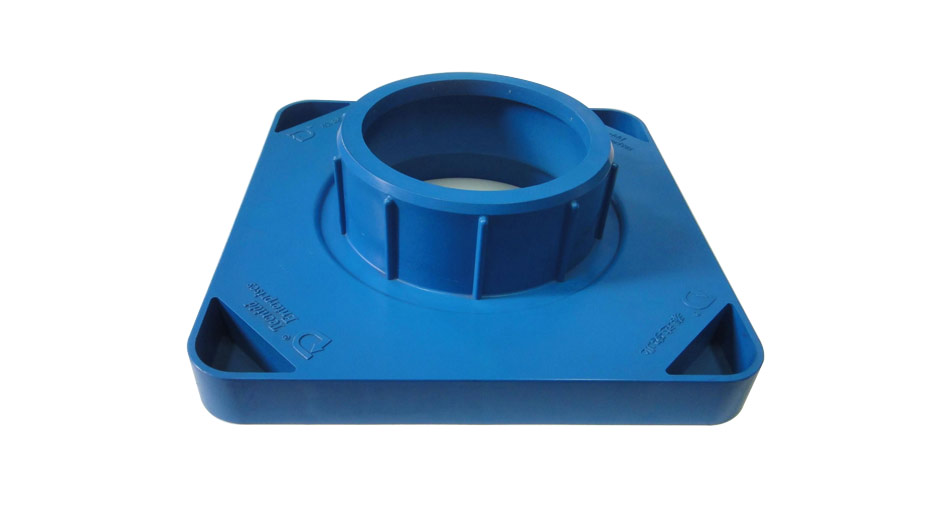

Product detail pictures:

Related Product Guide:

Cooperation

We have quite a few great team customers very good at internet marketing, QC, and dealing with kinds of troublesome trouble while in the output approach for 8 Year Exporter Mechanical Design - Plastic Injection – Protom, The product will supply to all over the world, such as: Doha , Los Angeles , Guyana , Many years of work experience, we have now realized the importance of providing good quality products and solutions and the best before-sales and after-sales services. Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it. faster delivery time and the product you want is our Criterion .

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.