2019 Latest Design Titanium Machining - Soft Tooling – Protom Detail:

With orders of more than 100 parts, we will consider Quick Turn Tooling, Injection Molding for plastics and Die Casting for metals. Materials could be plastics and metals. We can make rapid tooling for various plastics with different finishing, like sand blasting, texture, painting, plating and so on, depending on our customers’ requirements.

What is rapid tooling?

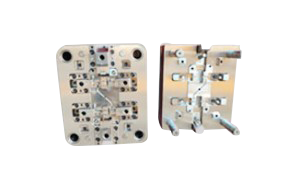

Rapid Tooling is a way to simplify the mold structure for low cost & short lead-time. It’s commonly used in the field of rapid injection molding, based on the low-volume requirement. Nice Rapid manufactures its own rapid tooling in 7075 aluminum(mold can be textured) and pre-hardened P20 tool steel, to make the cavity, core and ejector plates. They are then fitted into a Master Unit Die(MUD based system) with standard tooling components, in order to produce injection molded parts.

Rapid Tooling vs Conventional Tooling?

Aluminum tooling is very suitable or low-volume production prototype runs, providing a cost effective solution with shorter lead-time than traditional production tooling. For rapid tooling, we can typically be 30-50% cheaper than full production tooling, with a 40-60% reduction in lead-time compared to traditional

Product detail pictures:

Related Product Guide:

Cooperation

To consistently enhance the management method by virtue of the rule of "sincerely, fantastic religion and top quality are the base of business development", we extensively absorb the essence of associated goods internationally, and constantly acquire new merchandise to satisfy the needs of shoppers for 2019 Latest Design Titanium Machining - Soft Tooling – Protom, The product will supply to all over the world, such as: Detroit , Angola , United Arab Emirates , Please really feel free to send us your requirements and we'll respond to you asap. We have got a professional engineering group to serve for your just about every detailed needs. Cost-free samples could be sent for you personally to understand much more information. In an effort to meet your requires, please really feel free to make contact with us. You may send us emails and contact us directly. Moreover, we welcome visits to our factory from around the globe for much better recognizing of our organization. nd items. In our trade with merchants of numerous countries, we usually adhere for the principle of equality and mutual benefit. It is actually our hope to market, by joint efforts, each trade and friendship to our mutual advantage. We look forward to getting your inquiries.

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.